Unveiling the Advantages of Metal Castings over Fabrication Processes

When it comes to manufacturing metal components, two prominent methods stand out: metal casting and fabrication. While both techniques have their merits, metal casting offers a range of distinct advantages that make it a preferred choice for many industries. Here, we explore the advantages that metal castings have over fabrication processes, highlighting their efficiency, cost-effectiveness, versatility, and ability to produce complex shapes.

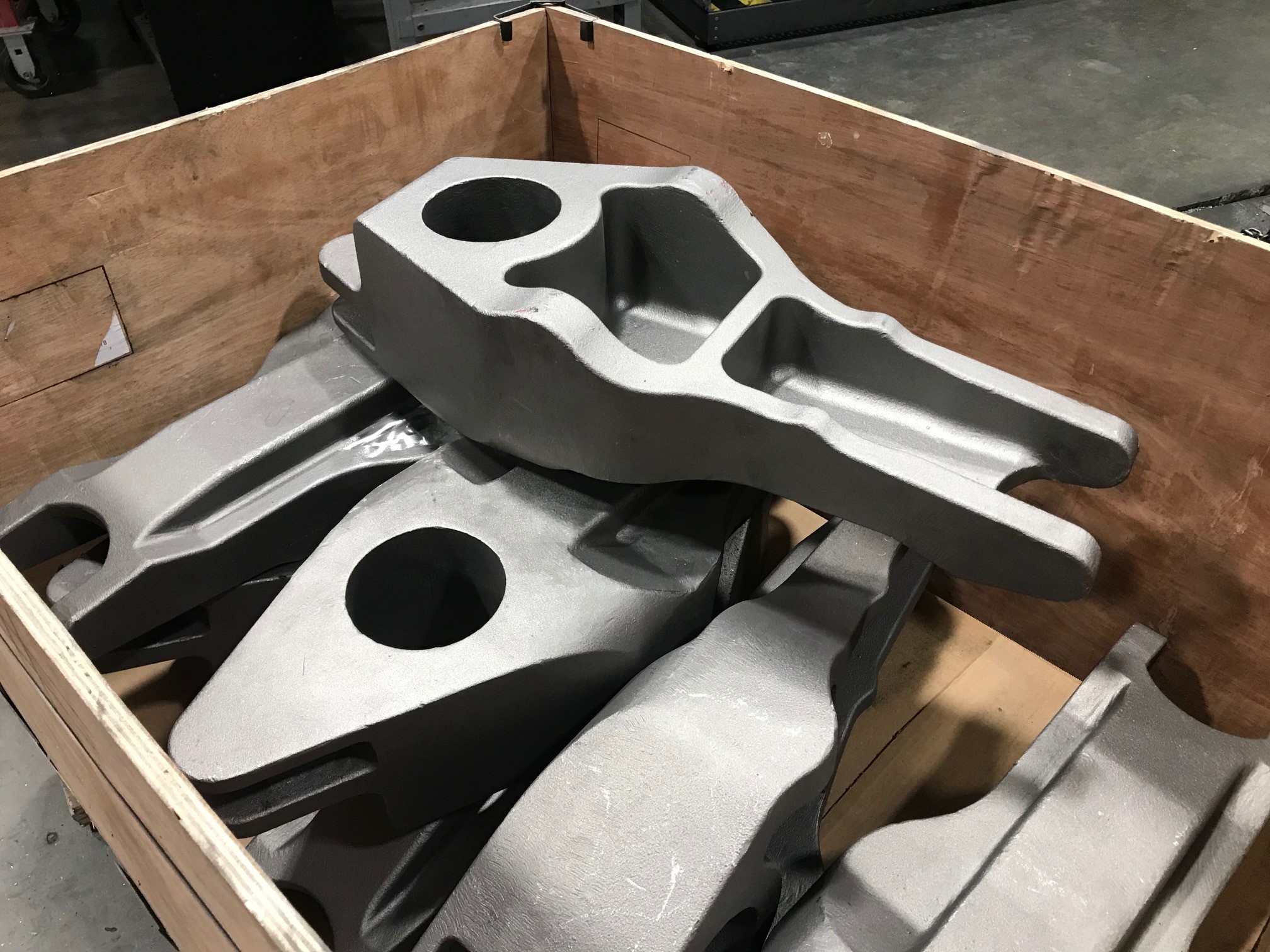

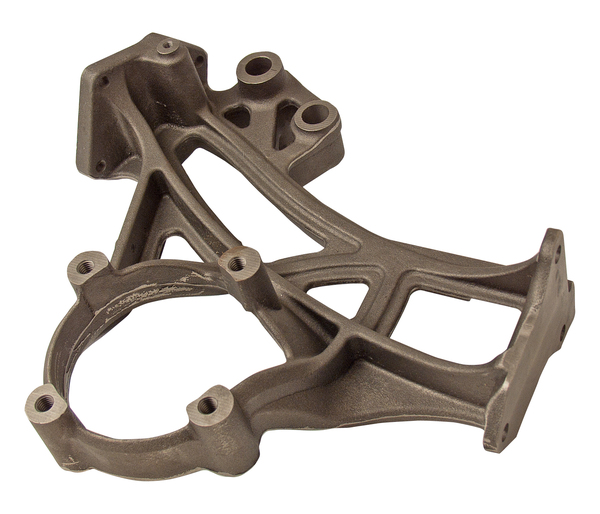

Complex Geometry and Design Freedom: Metal casting excels in producing intricate and complex geometries that would be challenging or impossible to achieve through fabrication processes. By using molds, metal can be poured into intricate shapes with fine details, internal cavities, and varying thicknesses. This versatility allows for the creation of components that have intricate internal features or unique external designs. Whether it's a turbine blade with precisely engineered contours or a customized industrial casting, metal casting provides engineers and designers with unparalleled design freedom.

Complex Geometry and Design Freedom: Metal casting excels in producing intricate and complex geometries that would be challenging or impossible to achieve through fabrication processes. By using molds, metal can be poured into intricate shapes with fine details, internal cavities, and varying thicknesses. This versatility allows for the creation of components that have intricate internal features or unique external designs. Whether it's a turbine blade with precisely engineered contours or a customized industrial casting, metal casting provides engineers and designers with unparalleled design freedom.

Material Efficiency and Waste Reduction: One of the key advantages of metal casting is its superior material efficiency. Casting techniques, such as investment casting or sand casting, enable near-net-shape production. This means that the castings require minimal post-processing or machining, resulting in less material waste compared to fabrication processes. With fabrication, excess material is often removed through cutting, milling, or grinding, leading to higher material wastage. Metal casting minimizes such waste, making it a more sustainable and cost-effective solution.

Cost-Effectiveness: Metal casting offers significant cost advantages, particularly in large-scale production. Once the initial casting mold or pattern is created, it can be used repeatedly to produce multiple identical components. This leads to economies of scale, reducing the cost per unit. On the other hand, fabrication processes often require individual fabrication or machining for each component, resulting in higher labor and tooling costs. Metal casting's ability to streamline production and achieve mass production efficiently makes it an economically viable choice for industries requiring high volumes of components.

Cost-Effectiveness: Metal casting offers significant cost advantages, particularly in large-scale production. Once the initial casting mold or pattern is created, it can be used repeatedly to produce multiple identical components. This leads to economies of scale, reducing the cost per unit. On the other hand, fabrication processes often require individual fabrication or machining for each component, resulting in higher labor and tooling costs. Metal casting's ability to streamline production and achieve mass production efficiently makes it an economically viable choice for industries requiring high volumes of components.

Strength, Durability, and Material Selection: Metal castings possess exceptional strength, durability, and the ability to withstand demanding operating conditions. The casting process allows for the selection of specific alloys and heat treatments, tailoring the mechanical properties of the cast parts to meet the required specifications. This flexibility enables manufacturers to produce components with high tensile strength, resistance to corrosion, heat resistance, and superior wear characteristics. Fabrication processes, on the other hand, may involve welding or joining multiple pieces, which can lead to weaker points and potential structural vulnerabilities.

Versatility in Material Choice: Metal casting provides a broad range of material choices, including various metals and alloys. From aluminum and steel to copper, bronze, and even exotic alloys, metal castings can be tailored to meet specific application requirements. This versatility allows manufacturers to select the ideal material with the desired properties, such as high conductivity, lightweight, or superior chemical resistance. Fabrication processes may be limited to working with certain materials or require additional steps to achieve the desired material properties.

Versatility in Material Choice: Metal casting provides a broad range of material choices, including various metals and alloys. From aluminum and steel to copper, bronze, and even exotic alloys, metal castings can be tailored to meet specific application requirements. This versatility allows manufacturers to select the ideal material with the desired properties, such as high conductivity, lightweight, or superior chemical resistance. Fabrication processes may be limited to working with certain materials or require additional steps to achieve the desired material properties.

While fabrication processes have their merits, metal casting outshines them in several aspects. The ability to produce complex shapes, superior material efficiency, cost-effectiveness in large-scale production, strength and durability, and the versatility in material choice are key advantages that metal castings bring to the table. These advantages make metal casting a preferred method for industries ranging from automotive and aerospace to energy and construction. By leveraging the unique benefits of metal casting, manufacturers can unlock new possibilities, innovation, and efficiency in their production processes.