Prototype Metal Castings

Prototype Metal Castings

We use state-of-the-art software and robust manufacturing processes to produce high quality metal castings poured with production grade materials using the sand and investment casting processes.

Metal alloys include:

- Grey, ductile, and austempered ductile iron (ADI)

- Ductile Ni-resist (A439)

- Silicon moly irons (Si-Mo)

- Solution Strengthened Ferritic Ductile Iron (SSFDI)

- Carbon, stainless, and tool steels

- Non-ferrous - aluminum, zinc, brass, and bronze

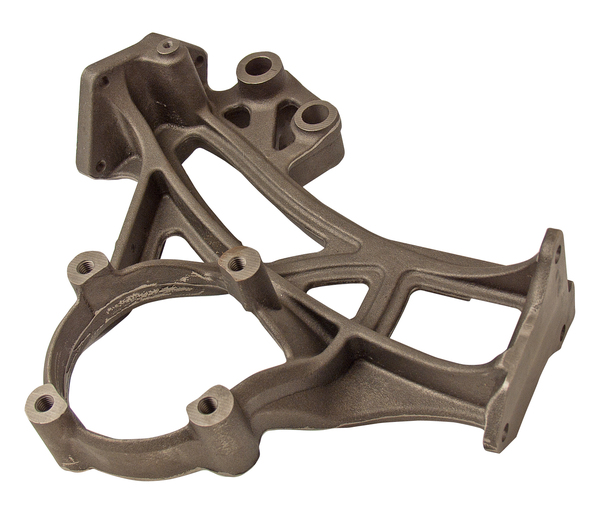

Sand Cast Metal Prototypes

We use customer supplied 3D CAD files to manufacture prototype tooling and 3D printed molds and cores for use in our sand casting operation. The S-Max sand printer allows us to reduce lead-times, as well as produce complex casting geometries and "one-off" prototypes in an accelerated timeframe. Typical lead time for delivery of castings ranges from 1-2 weeks using 3D printed molds to 3-4 weeks for traditionally tooled parts. ***Accelerated deliveries are possible; please contact us to discuss your project needs.***

Our ferrous and non-ferrous melting operations are strictly controlled to ensure molds are poured with the proper alloy. Our metal casting facilities are capable of pouring ferrous castings up to 800 lbs. and aluminum castings up to 200 lbs. Secondary machining ops are used control critical features and part dimensions.

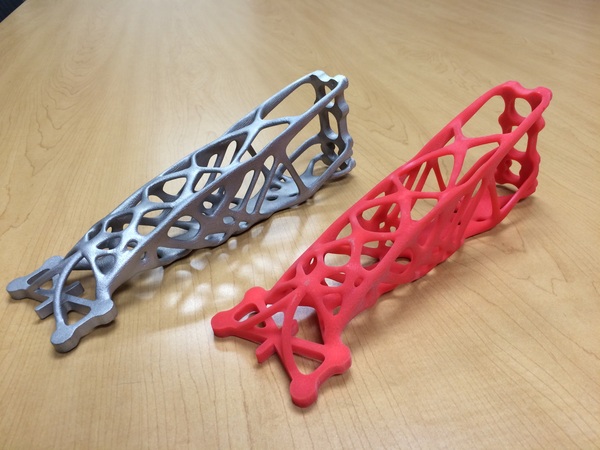

Investment Cast Metal Prototypes

Investment castings are an excellent choice for small, highly detailed prototype parts. Patterns can be produced using conventional tooling or via 3D printing technologies.

Investment casting is an excellent choice for smaller, highly detailed parts. Delivery of raw castings is typically 2-3 weeks and machining may or may not be needed to control part specific tolerances.