Don’t let 3D Printing Derail Your Plans

3D printing in the casting industry has revolutionized prototyping by enabling faster lead times, enhanced design freedom, cost efficiency, customization, and implementation of an iterative design process. It has paved the way for a more agile, innovative, and customer-centric approach to bringing castings to market.

3D printing in the casting industry has revolutionized prototyping by enabling faster lead times, enhanced design freedom, cost efficiency, customization, and implementation of an iterative design process. It has paved the way for a more agile, innovative, and customer-centric approach to bringing castings to market.

However, the luxuries of the technology can also serve to undermine your long-term objectives if Design for Manufacturability (DFM) is not properly taken into account during the prototyping process. It pays to keep the end game in mind, ensuring that your design is set up to successfully transition from a prototype to a production environment.

Keeping Expectations in Check

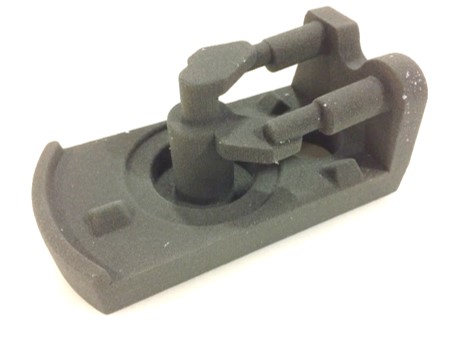

Let’s face it, as an engineer you can “get away with murder” using 3D printing. Undercuts, no draft, complex geometry…the 3D printer doesn’t care. Generally speaking, if you can model it, you can 3D print it. While it’s certainly appealing to have access to design freedoms not afforded by traditional manufacturing, eventually the “chickens will come home to roost” and your casting will have to transition to a production process.

To aid in that transition, simplify the design and minimize part complexity whenever possible. Complex geometries, thin walls, and intricate features can complicate the casting process and increase the risk of defects. By reducing complexity early on, you make it easier to achieve uniform filling, proper solidification, and good surface finish during production while simplifying the mold-making process, reducing cost and driving down lead times.

To aid in that transition, simplify the design and minimize part complexity whenever possible. Complex geometries, thin walls, and intricate features can complicate the casting process and increase the risk of defects. By reducing complexity early on, you make it easier to achieve uniform filling, proper solidification, and good surface finish during production while simplifying the mold-making process, reducing cost and driving down lead times.

Leverage Your Suppliers

It’s important to establish open communication and collaboration with your casting suppliers. Engage them early in the prototyping process and involve them in design reviews. Their expertise and experience can provide valuable insights and recommendations for optimizing the design for manufacturing. Collaborative discussions can help address potential challenges, optimize the design for casting, and improve overall quality and efficiency.

Familiarize yourself with the specific casting design guidelines recommended by the foundry. These guidelines provide valuable insights into the capabilities and limitations of the casting process. While 3D printing can offer an attractive near-term solution that short circuits constraints, adhering to these guidelines from the outset ensures that your design aligns with the long-term production process requirements.

Familiarize yourself with the specific casting design guidelines recommended by the foundry. These guidelines provide valuable insights into the capabilities and limitations of the casting process. While 3D printing can offer an attractive near-term solution that short circuits constraints, adhering to these guidelines from the outset ensures that your design aligns with the long-term production process requirements.

Design with the End Game in Mind

As a game changing and disruptive technology, 3D printing has revolutionized the metal casting industry and allowed us to do things that were previously not practical or possible. However, don’t let the freedoms afforded by the 3D printing process get in the way of achieving your goals.

From the start of the prototyping process, DFM considerations should be balanced with the specific requirements and goals of your casting. It is essential to strike a balance between manufacturability, functionality, performance, and cost to achieve an eventual successful transition from prototype to production.