If You're Not Using Process Simulation Software, You Should

In the world of manufacturing, precision and efficiency are key factors for success. However, in the metal casting industry, achieving optimal casting quality and efficiency can be a challenging task. That's where powerful process simulation software such as EKKcapcast, NovaCast, or MAGMASOFT come into play.

Casting process simulation software offers a comprehensive understanding of the entire casting process, enabling engineers to optimize various parameters to achieve the desired outcomes. This powerful tool has revolutionized the casting industry by enabling engineers to visualize and optimize the casting process before any physical prototypes are created.

Improved Quality

One of the primary advantages of using a casting process simulation software is the ability to enhance casting quality using minimal physical resources. By simulating the process digitally, metal casters can identify and rectify potential defects and optimize the design and production parameters accordingly.

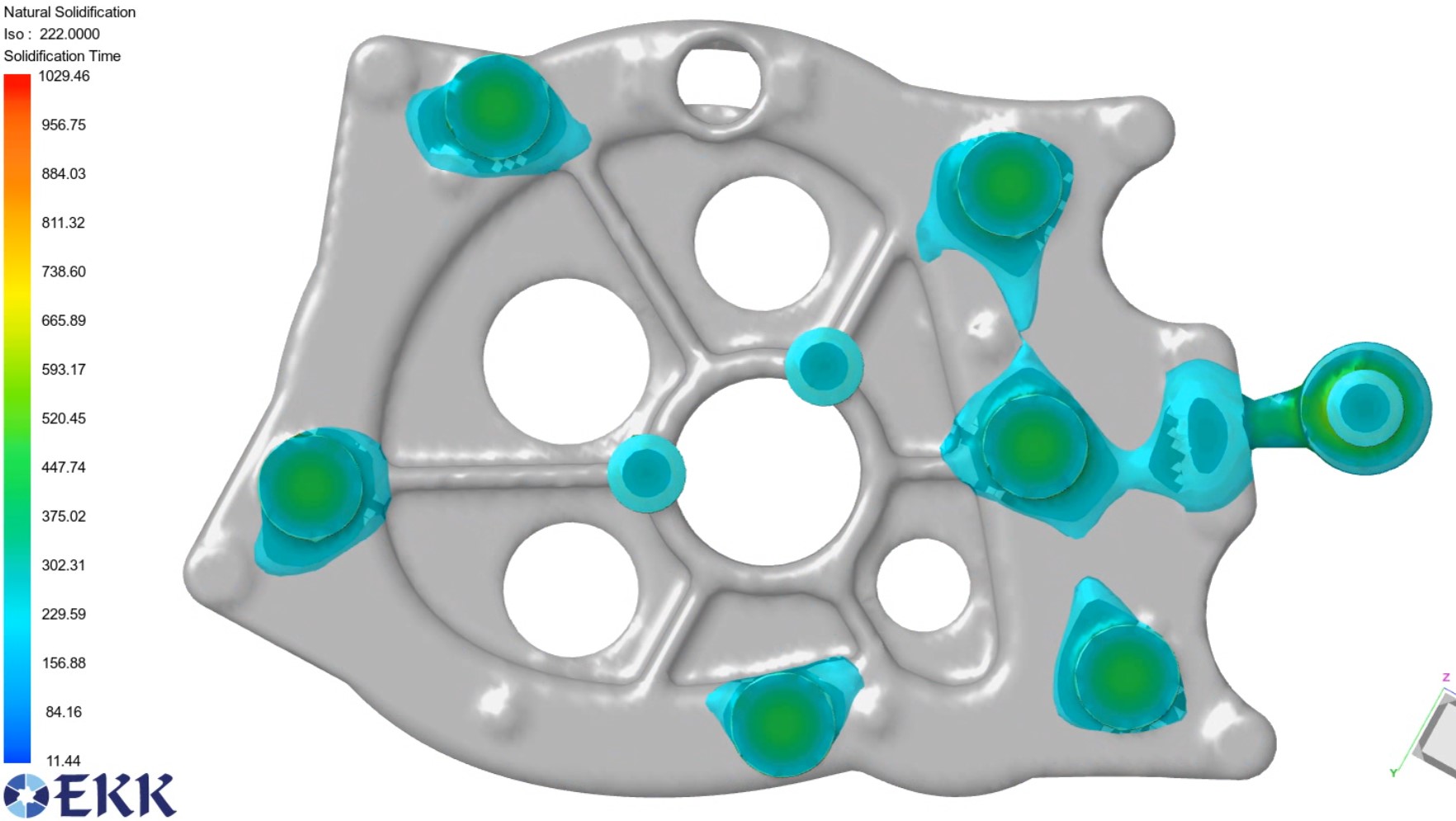

The software provides insights into issues such as shrinkage, porosity, gas entrapment, and solidification patterns, allowing foundries to make informed decisions and improve the overall casting quality. Foundries can evaluate the impact of changes in real-time and fine-tune the process accordingly. This optimization leads to improved yield, reduced scrap rates, and enhanced overall efficiency.

Solidification analysis of an iron casting using EKKcapcast

Cost and Time Savings

Traditional trial-and-error casting methods can be time-consuming and expensive, involving multiple physical prototypes and iterations. Utilizing simulation software eliminates, or greatly reduces, the need for many of these trials, saving both time and money.

By accurately predicting the behavior of the molten metal, the software helps optimize various parameters, such as gating and riser design, cooling rates, and mold filling patterns, thus reducing the number of samples or trials required to successfully produce a good part.

Enhanced Collaboration and Communication

Simulation Software provides a visual representation of the entire casting process, making it easier for engineers, designers, and other stakeholders to understand and communicate effectively. With a shared digital platform, teams can collaborate seamlessly, exchange ideas, and discuss potential improvements. This collaborative approach fosters innovation, accelerates decision-making, and ultimately leads to better casting outcomes.

Conclusion

Simulation software has emerged as an indispensable tool for ensuring the success of the casting process. From improving casting quality and reducing costs to enabling process optimization and facilitating design validation, simulation software empowers engineers to make informed decisions, minimize risks, and enhance overall efficiency. By embracing this technology, manufacturers can confidently produce high-quality components while remaining agile in a competitive market.